|

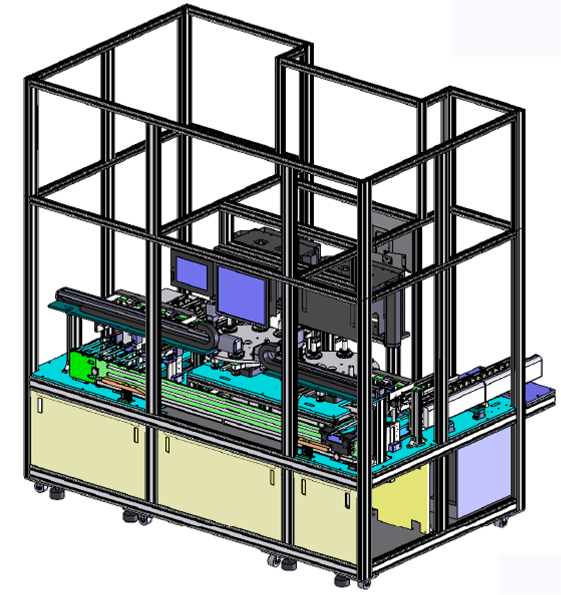

DSIS 100 Disk InspectionSeidensha's Disk Surface Inspection System 100 (DSIS 100) is an ideal solution to a more effective and efficient stringent quality control of magnetic disk media. DSIS is an automated solution for defects inspection of the edge and surface of magnetic disk media. The solution comprised of:

DSIS minimizes human handling during inspection and human error in defects identification. The system automatically sorts out defective disks and stores the image of the disks inspected. Users can define the specification for rejection of defective disk. The system comes equipped with a control server and a data server which transfers data to the local network promptly for reporting purposes. It comes with a user-friendly interface which makes ease for the use of the machine for different groups of people such as technicians and engineers. Dimensions

Operating Environment Requirements

Electrical Requirements

Air Input Requirements

|